Introduction:

Protein purification is a crucial step in various scientific and industrial processes, such as drug development, biotechnology, and biochemical research. It involves the isolation and separation of proteins from complex biological mixtures to obtain highly pure and bioactive proteins. One of the essential tools used in protein purification is the peristaltic pump. This essay aims to explore the functionality of peristaltic pumps in protein purification, highlighting their advantages, limitations, and potential future developments.

Body:

1. Definition and Working Principle of Peristaltic Pumps:

Peristaltic pumps are positive displacement pumps that use a squeezing action to move fluids through a flexible tubing. They operate based on the principle of peristalsis, mimicking the rhythmic contraction of muscles in the human digestive system. As the pump's rotating rollers compress and release the tubing, it creates a series of occlusions that propel the fluid in a forward direction.

2. Advantages of Peristaltic Pumps in Protein Purification:

a) Gentle and Non-Damaging: Peristaltic pumps are known for their gentle pumping action, which minimizes the risk of protein denaturation or degradation. The absence of valves or seals in the fluid path further reduces the chances of contamination or damage to the protein sample.

b) Versatility: Peristaltic pumps can handle a wide range of viscosities, making them suitable for various protein purification techniques. Whether it involves gravity flow chromatography, affinity chromatography, or gel filtration, peristaltic pumps can effectively pump the protein sample without compromising its integrity.

c) Precise Control: These pumps offer excellent control over flow rates, allowing researchers to optimize purification conditions. By adjusting the speed of the pump, the flow rate can be precisely regulated, ensuring efficient separation and elution of proteins.

d) Ease of Use and Maintenance: Peristaltic pumps are relatively simple to operate and maintain. The tubing used in these pumps can be easily replaced, preventing cross-contamination between different protein samples. Additionally, the absence of moving parts in contact with the fluid simplifies cleaning and sterilization procedures.

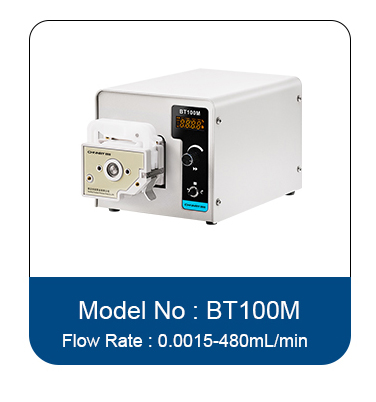

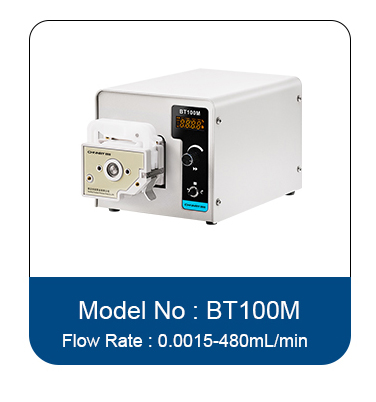

CHONRY Peristaltic pump for protein purification for sale

3. Future Developments and Improvements:

a) Enhanced Flow Rates: Ongoing research aims to improve the flow rates of peristaltic pumps without compromising their gentle pumping action. Engineering advancements may lead to the development of peristaltic pumps suitable for large-scale protein purification.

b) Tubing Optimization: The development of novel tubing materials with improved protein compatibility is an area of active research. Such advancements would further enhance the performance and reliability of peristaltic pumps in protein purification.

c) Integration with Automation: The integration of peristaltic pumps with automated systems can streamline protein purification workflows, reducing human error and increasing efficiency. Future developments may focus on enhancing the compatibility and control of peristaltic pumps within automated platforms.

Conclusion:

Peristaltic pumps play a vital role in protein purification, offering numerous advantages such as gentle pumping action, versatility, precise control, and ease of use. Despite their limitations, ongoing research and development efforts aim to address these challenges, paving the way for improved flow rates, optimized tubing materials, and integration with automation. As scientific and industrial demands for highly pure proteins continue to grow, peristaltic pumps are likely to remain an indispensable tool in protein purification processes.