What Is Mechanical Polishing?

Chemical mechanical polishing refers to the use of a polishing machine, polishing fluid, polishing cloth and other processes under certain conditions to achieve high surface flatness of the processing process, in which the supply of polishing fluid by the peristaltic pump to complete.

Polishing fluid is a kind of water-soluble polishing agent without any sulfur, phosphorus and chlorine additives. The polishing fluid has good degreasing, rust prevention, cleaning and polishing properties, and can make metal products show real metallic luster. Stable performance, non-toxic, no environmental pollution, and so on.

Type of polishing liquid: Polishing agent for silicon material / Sapphire polishing fluid / Gallium arsenide polishing solution / Lithium niobate polishing solution/ Germanium polishing solution / Integrated circuit multiple copper wiring polishing fluid / Integrated circuit barrier polishing fluid.

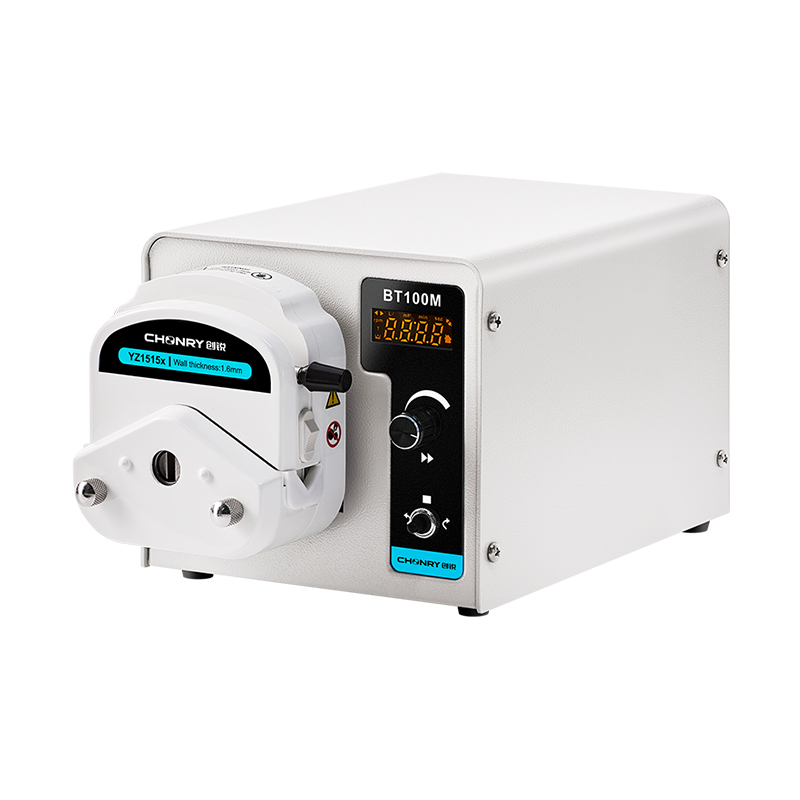

Most of the Polishing Fluid Can Be Transferred by Chonry® Peristaltic Pump

The peculiar structure of the peristaltic pump, which separates the pumping fluid from the pump body strictly, and the pump tube and the pump head can be replaced at any time. That makes the advantages of the peristaltic pump in the chemical polishing process very obvious.

(1) Non-pollution: In the chemical polishing process, the polishing fluid conveyed by Chonry® peristaltic pump is always flowing in the pump tube, not contacting the pump body, especially not contacting the mechanical transmission mechanism. It avoids metal pollution in the process of chemical mechanical polishing and also not damage the mechanical components of the pump body due to the corrosiveness of the polishing fluid.

(2) Self-priming ability: Chonry® peristaltic pump can produce enough vacuum suction to suck polishing fluid from the night pool into the pump pipe during the working process, thus eliminating the pre-filling process of pump and suction pipe. This also eliminates the need for submerged filling, so it is no longer necessary to place the pump below the liquid source level, making the installation position of the pump more flexible and better integrated with the polishing machine itself. Besides, the water in the peristaltic pump will not be lost, so it can avoid unnecessary stopping.

(3) Simple operation: Chonry® peristaltic pump operation is very simple, pump pipe installation, disassembly, locking can be carried out at any time according to requirements. Besides, the peristaltic pump is simple to control, and the speed control can be carried out by using the speed control knob or the operation panel. In addition, according to different flow requirements can also be a peristaltic pump at the same time 2 or 3 pump heads in series, to achieve a multi-channel supply of polishing fluid.

Application

1. LED industry

At present, the substrate material of LED chips is sapphire, which needs to be thinned and polished during processing. The hardness of sapphire is very high, and ordinary abrasive is difficult to process. After the sapphire substrate is thinned and roughened with diamond grinding fluid, some large or small scratches are unavoidable. CMP polishing fluid has achieved the precision polishing of sapphire surfaces by using the principle of "soft grinding and hard". With the rapid development of LED industry, the demand for polycrystalline diamond grinding fluid and silica sol polishing fluid is increasing.

2. semiconductor industry

CMP technology is also widely used in the polishing of silicon wafers in integrated circuits (IC) and ultra-large scale integrated circuits (ULSI).

With the rapid development of the semiconductor industry, new requirements have been put forward for polishing technology. Although traditional polishing technology (such as selective deposition and sputtering based on deposition technology) can also provide a "smooth" surface, they are all local planarization technology, which can not achieve global planarization, and chemical mechanical polishing technology solutions. To solve this problem, it is the only technology that can flatten the whole wafer completely at present.

Related Products