The Introduction of Fiberglass Industry

Glass fiber is an inorganic non-metallic material with excellent performance. It has the advantages of good insulation, strong heat resistance, good corrosion resistance, and high mechanical strength. Glass fiber is generally made of glass balls or waste glass, and is made through high-temperature melting, wire drawing, winding, weaving and other processes. The diameter of its single filament is a few microns to more than 20 microns, which is equivalent to 1/20-1/5 of a hair. Each fiber strand is composed of hundreds or even thousands of single filaments. Glass fiber is a very good metal substitute material. It is usually used as a reinforcing material, electrical insulation material and thermal insulation material in composite materials. Fiberglass products are widely used in various industries, including:

- Automotive (body panels, insulation)

- Aerospace (aircraft components)

- Construction (insulation, roofing)

- Marine (boat hulls, components)

- Sports equipment (bicycles, skis)

The Production Line of Fiberglass Industry

The raw materials are dissolved into glass solution, clarified and homogenized, and then flow out through a porous plate made of platinum-rhodium alloy, forced to cool the wire roots through a cooler, and are pulled at high speed by a wire drawing machine to form fibers. The formed single fibers are coated with a wetting agent by an oiler, bundled into raw fiber bundles, and then orderly wound into wire cakes by the wire drawing machine's wire arrangement device.

Peristaltic Pumps in Fiberglass Industry Transferring Anti-static Fluid

Glass fiber manufacturers use peristaltic pumps to accurately transfer antistatic liquid. Antistatic liquid is coated on the surface of glass fiber bundles to reduce the surface resistance of glass fiber and form a conductive channel, making it difficult for the surface of glass fiber to generate static electricity. At the same time, antistatic liquid reduces the friction coefficient during the subsequent processing of the fiber, plays a role in protecting and lubricating the glass fiber, and ensures that the short fibers are evenly distributed when users cut and spray.

The Demand of Peristaltic Pump to Transfer the Anti-Static Fluid

1. Antistatic liquid is volatile, easy to adhere, and has a certain degree of irritation, so it is required to achieve closed liquid transmission.

2. The flow rate is required to be 5mL/min, the flow rate is stable, and the repeatability flow rate accuracy is 3%.

3. The peristaltic pump can receive the signal from the anti-static liquid flow monitoring and adjustment device, and adjust the transmission flow of the antistatic liquid according to the signal.

4. The peristaltic pump is simple to operate and easy to maintain.

Recommend Chonry peristaltic pump for the fiberglass Industry

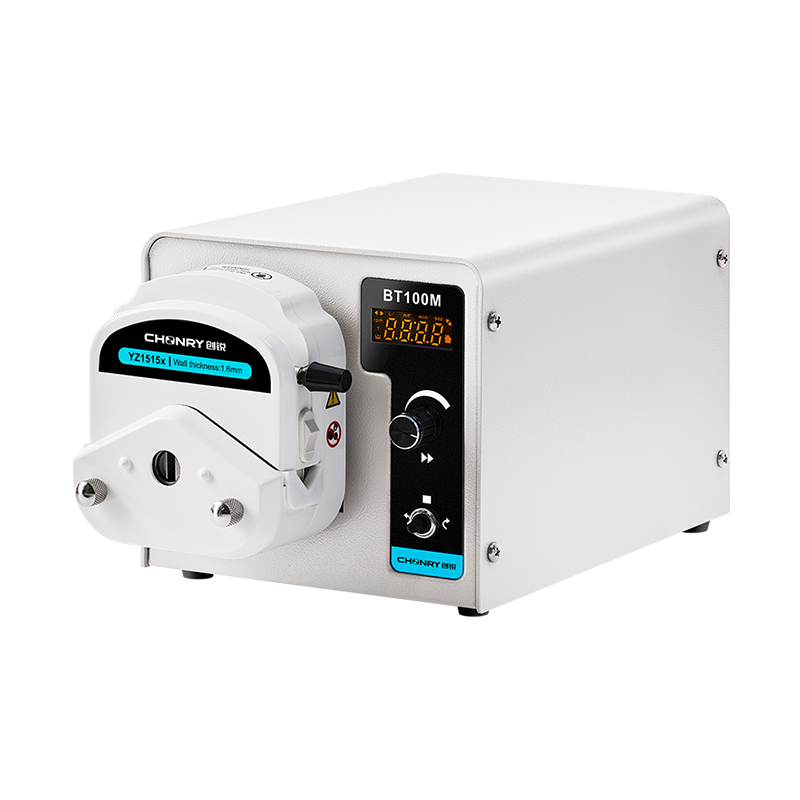

Chonry® peristaltic pump manufacturer recommends theBT100M/DG-1(10) multi-channel peristaltic pump and BT100M/YZ1515x constant flow peristaltic pump to solve the anti-static liquid transfer in fiberglass industry.

1. The peristaltic pump has good self-sealing performance. No valves and seals are required on the anti-static liquid transmission pipeline, and liquid backflow will not occur. Therefore, the leakage points in the anti-static liquid transmission process can be reduced, ensuring closed transmission.

2. The BT100M driver + DG-1 (10 roller) pump head can provide a flow range of 0.0015ml/min-27ml/min, which meets the customer's flow requirements. And because the 10 roller pump head has the characteristics of small pulsation and high flow stability, the flow accuracy of the transmitted liquid is 2%.

3. Peristaltic pump BT100M has the characteristics of compact structure, small size and light weight, which is easy to install and maintain.Continuous flow rate.