Introduction:

Lithium batteries have become a vital power source in various industries, including consumer electronics, electric vehicles, and renewable energy systems. The manufacturing process of lithium batteries involves precise fluid handling, and peristaltic pumps have emerged as a reliable solution for this application. This article will explore the significance and benefits of using peristaltic pumps in the field of lithium batteries.

Precise Fluid Delivery:

One of the critical requirements in lithium battery manufacturing is the precise delivery of various electrolytes, solutions, and viscous substances to different battery components. Peristaltic pumps excel in this aspect as they offer highly accurate flow control and pressure adjustment capabilities. By adjusting the pump's speed and the pressure applied on the tubing, peristaltic pumps ensure the precise ratios and injection volumes of liquids in each battery unit, ensuring manufacturing process stability and consistency.

Fluid Compatibility:

The manufacturing process of lithium batteries involves the use of different liquids and solutions with varying chemical properties and viscosities. Peristaltic pumps utilize replaceable tubing as the conveying channel, allowing them to adapt to diverse fluid requirements without causing contamination or chemical reactions. This fluid compatibility feature makes peristaltic pumps an ideal choice for lithium battery manufacturing.

Leakage-Free and Contamination-Free:

Any fluid leakage or contamination during the manufacturing process can negatively impact the battery's performance and safety. Peristaltic pumps operate on the principle of peristaltic motion, squeezing the tubing to convey fluids, thus eliminating the risks of leakage or contamination. This leakage-free and contamination-free characteristic ensures the integrity and reliability of the lithium batteries produced.

Flexibility and Scalability:

Peristaltic pumps offer flexibility and scalability in lithium battery manufacturing. They can handle a wide range of flow rates and pressures, accommodating various production requirements. Additionally, peristaltic pumps can be easily integrated into existing manufacturing setups, allowing for seamless scaling-up of production capacity.

Maintenance and Cost Efficiency:

Peristaltic pumps are known for their low maintenance requirements. The replaceable tubing is the only component that comes into contact with the fluid, reducing the need for frequent cleaning and maintenance. Moreover, the tubing replacement is a simple and cost-effective process, minimizing downtime and overall operating costs.

Chonry Solutions:

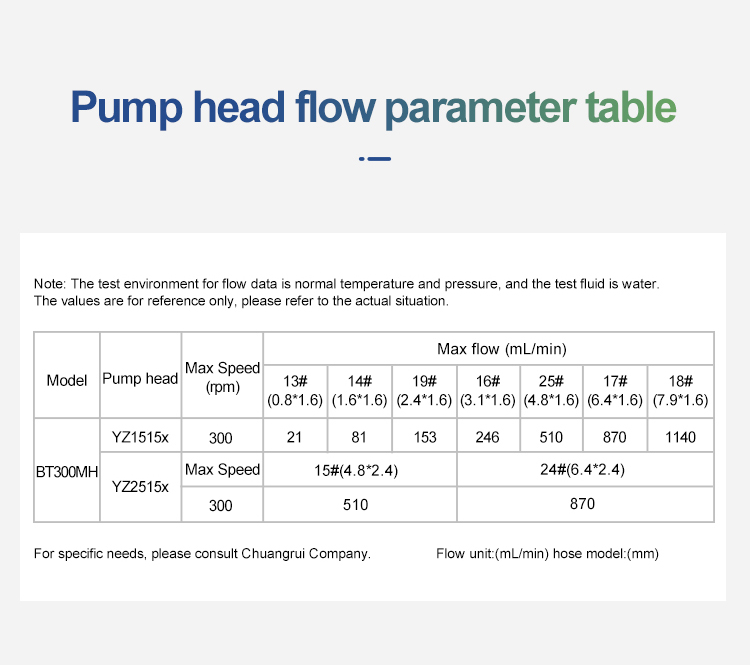

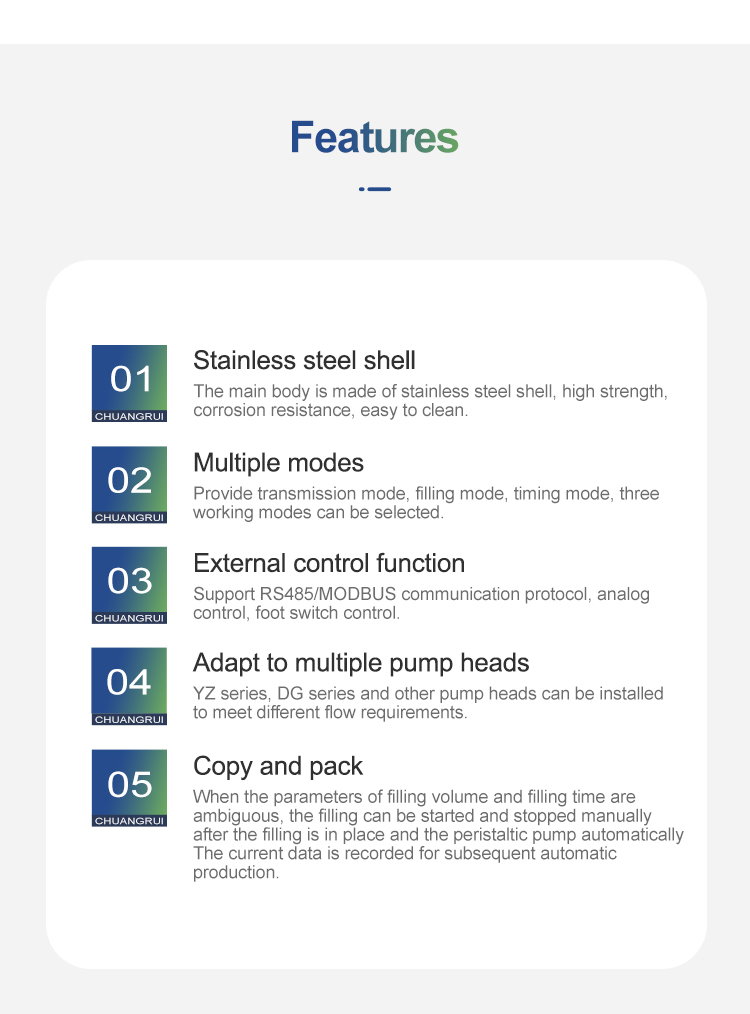

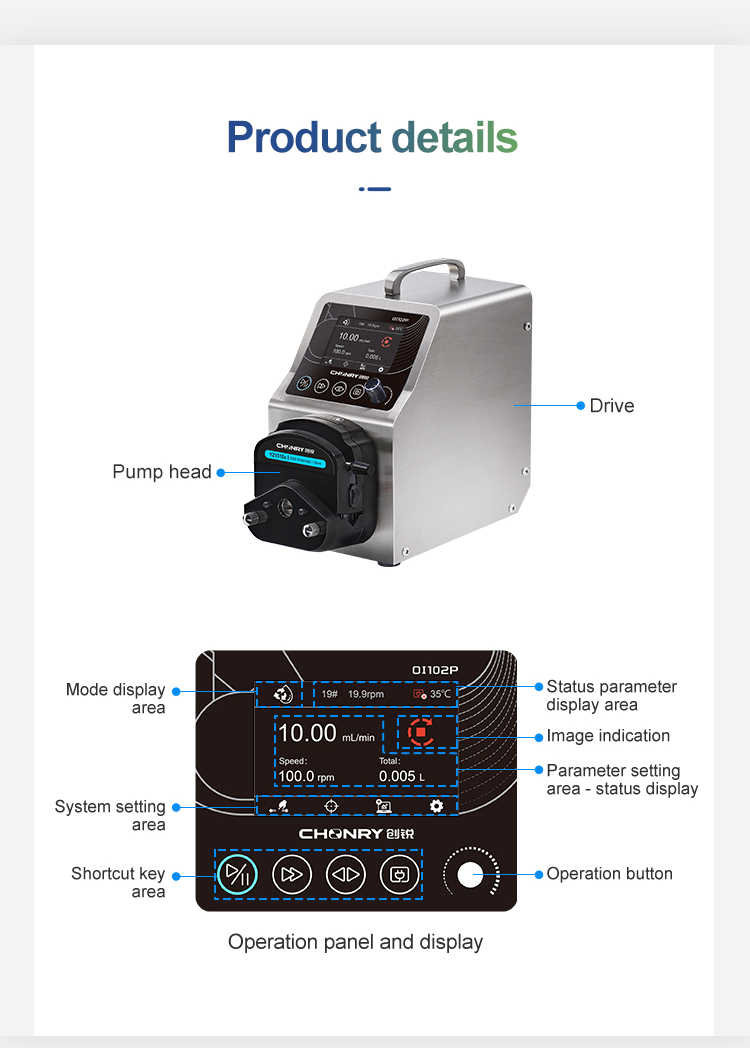

As the leading peristaltic pump manufacturer in China, we developed the OI series and MH series basic peristaltic pumps applied in the lithium batteries industry.

Both series peristaltic pumps adopt stainless shells. Durable and anti-corrosion. High-precision liquid transfer and filling. The operation interface is clear and simple.

The flow rate of the OI series peristaltic pump is from 0.0015 to 4560ml/min. Adopts knob operation, easy to operate. Three working models - filling, timed, and dispensing.

The flow rate of the MH series peristaltic pump is from 0.0015 to 2280ml/min. This is our basic type. Touch screen operation. Convenient full-speed button for quickly filling or emptying the tube.

Conclusion:

In the field of lithium battery manufacturing, peristaltic pumps play a vital role in ensuring precise fluid handling and delivery. Their high accuracy, fluid compatibility, leakage-free operation, and scalability make them an ideal choice for this application. By utilizing peristaltic pumps, manufacturers can achieve manufacturing process stability, consistency, and safety, thereby enhancing the performance and reliability of lithium batteries.