What is the peristaltic pump?

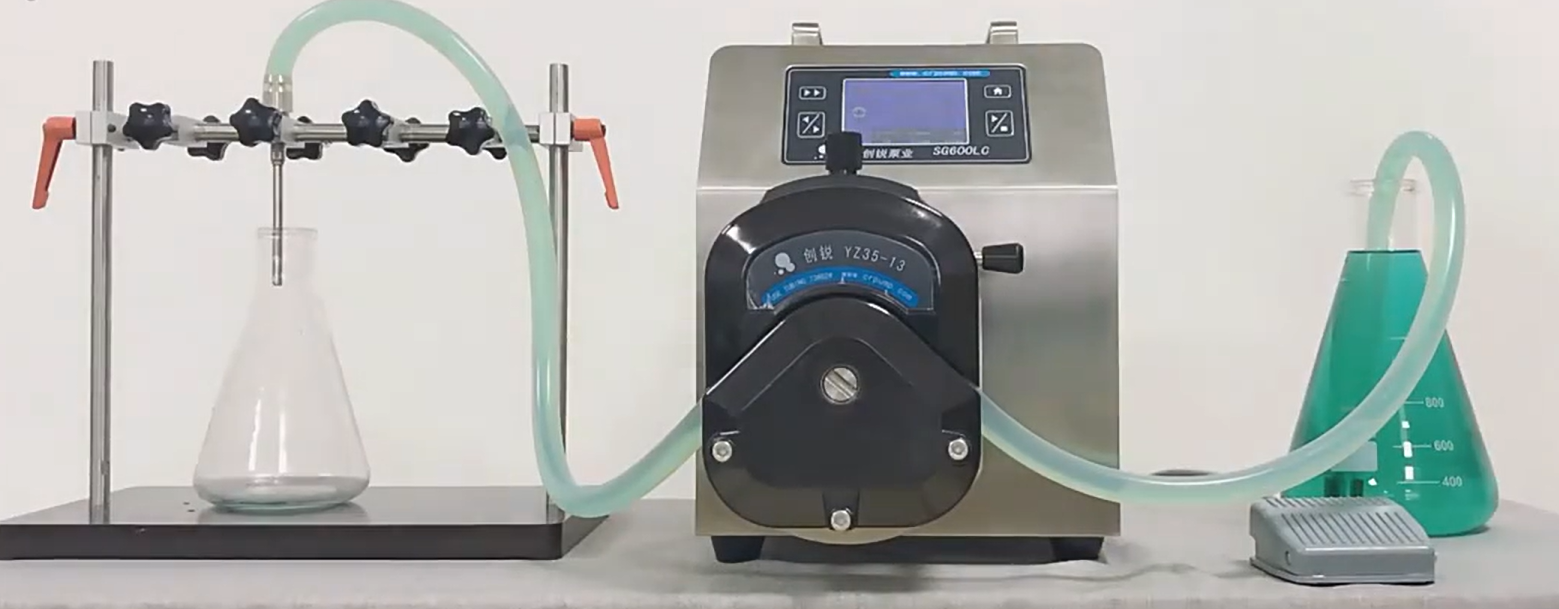

Peristaltic pumps are also called rotor pumps. The principle is to squeeze the hose through the rotation of the roller to make the liquid flow. The process is like swallowing an egg, squeezing and releasing a hose to transport liquid through the pulse of multiple rollers. The liquid only contacts the hose. The hose can be autoclaved to avoid contamination during the liquid transfer process. Generally, the peristaltic pump needs to work with different motors or drivers. Different pump heads of different peristaltic pumps match different motors and drivers, so as to meet the needs of customers with different flow ranges and different functions.

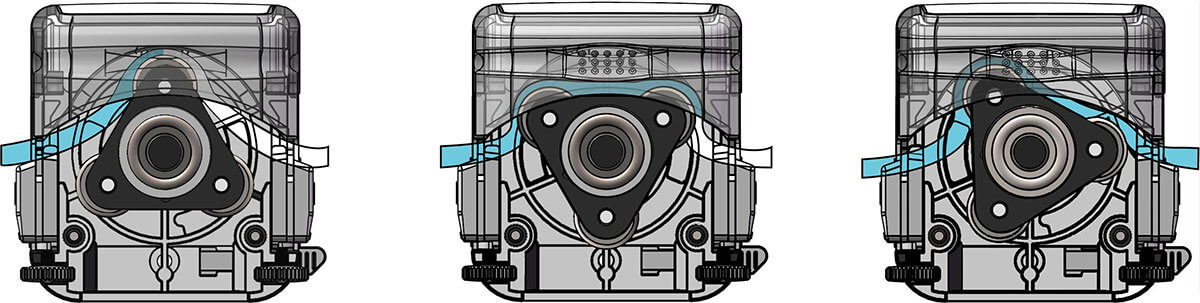

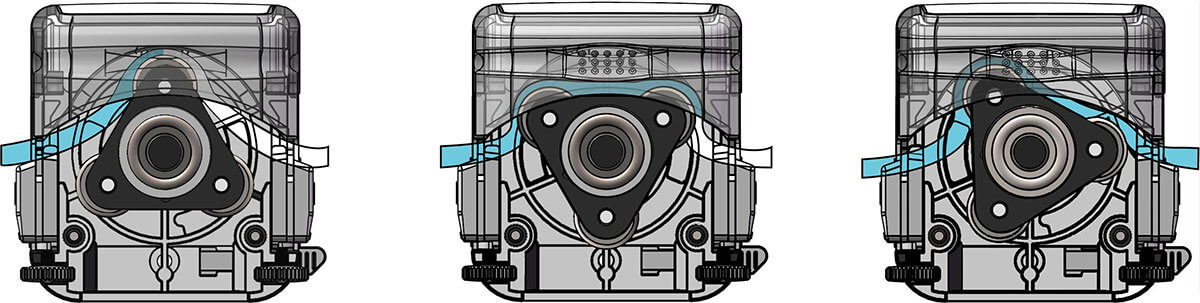

How does the peristaltic pump work?

Peristaltic pumps are like squeezing a fluid-filled hose with your fingers, and the fluid moves forward as the fingers slide along the tube. The principle of the peristaltic pump is just that the finger s replaced by the roller. Pump fluid by alternately squeezing and releasing the pump's flexible delivery hose. Just like pinching a hose with two fingers, as the fingers move, negative pressure builds up inside the tube and the liquid flows with it.

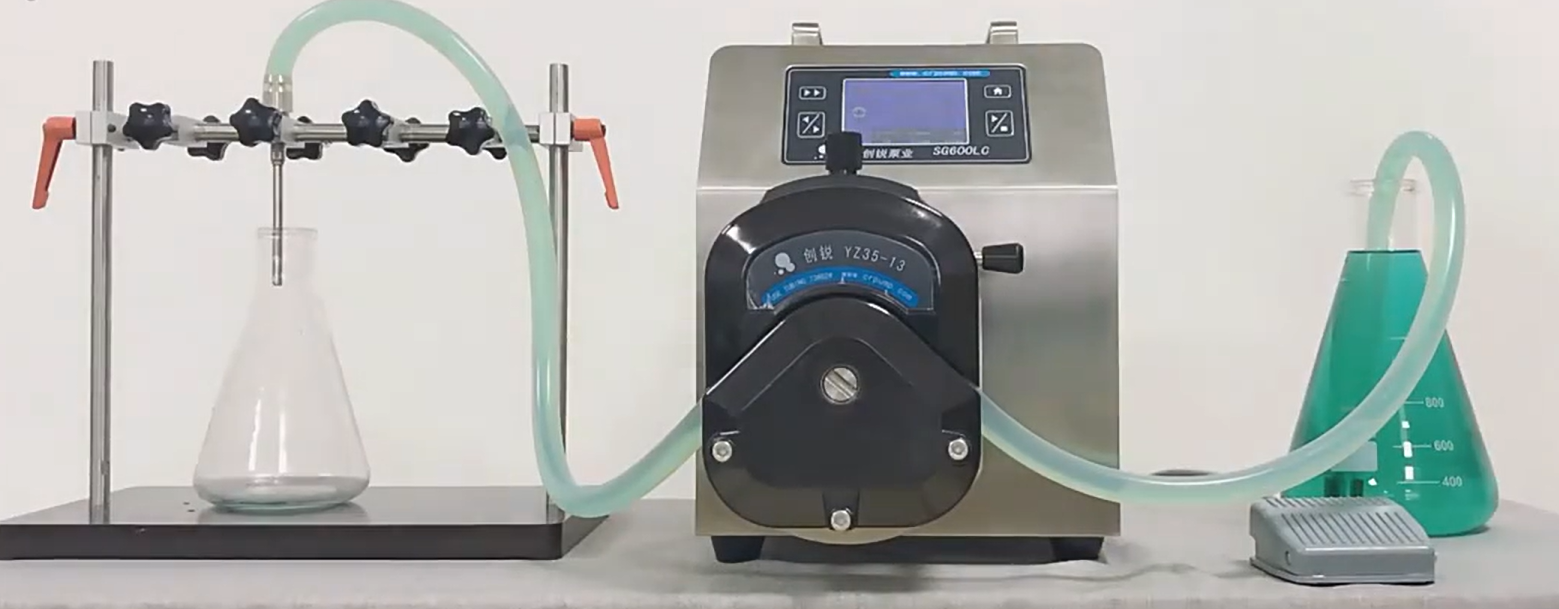

The peristaltic pump consists of three parts: driver, pump head, and hose. Chonry peristaltic pump combined with Chonry peristaltic pump drive can match hundreds of different peristaltic pumps.

The Advantage of Peristaltic Pump

· No contamination. Because the only part of the pump in contact with the fluid being pumped is the interior of the tube, it is easy to sterilize and clean the inside surfaces of the pump.

· Low maintenance needs. Their lack of valves, seals and glands makes them comparatively inexpensive to maintain.

· They are able to handle slurries, viscous, shear-sensitive, and aggressive fluids.

· Pump design prevents backflow and siphoning without valves.

· A fixed amount of fluid is pumped per rotation, so it can be used to roughly measure the amount of pumped fluid.

How to select a suitable peristaltic pump?

Before selecting the peristaltic pump, please learn about the viscosity, and corrosiveness of fluids. So that we can recommend the right peristaltic pump according to the fluids and other requirements.Three major factors affecting the choice of a peristaltic pump

1. Tube inner diameter(ID)

For a given rpm of the pump, a tube with a larger ID will give a higher flow rate than one with a smaller ID

2. Flow rate

Flow rate is an important parameter for a pump. The flow rate is determined by many factors, such as:

Tube ID - higher flow rate with larger ID

Pump head RPM - higher flow rate with higher RPM

Inlet Pulsation - the pulse reduces the filling volume of the hose

3. Pulsation

Pulsation is an important side effect of the peristaltic pump. The pulsation is determined by many factors, such as:

Flow Rate - higher flow rate is more pulsation

Line Length - Long pipelines is more pulsation

Higher Pump Speed - higher RPM is more pulsation

Higher fluid density is more Pulsation

Can the peristaltic pump be controlled by PLC?

Yes. As a leading peristaltic pump supplier, Chonry peristaltic pumps support Modbus communication protocol. We support the external control interface and cable depending on your requirement.

About the external control: Our basic type pump with a stepper motor or servo motor are with the external control options :

1. For small batch filling ---- foot switch is enough

2. For bulk batch filling which needs to work with the production: our pump support :

· RS485/RS232 communication protocol

· Analog control (0-5v 0-10v 4-20mA optional )

· Start/stop control

· Direction control

For example: for the coating machine supporting pump always use the 4-20mA external control

What's the application for the pump?

The peristaltic pump system is suitable for laboratory, industrial manufacturing, and field applications, used in the chemical industry; mining, metallurgy industry; paper industry; paint and coating industry; food industry; ceramic industry; petroleum industry; water treatment industry. Agriculture: dosing of feed additives, insecticide spraying, biotechnology: chromatographic plates, circulating cell suspension during fermentation, agar injection into Petri dishes, filtration chemical industry: corrosive cleaners, elutriation, flow injection analysis, tissue infusion, injection measurement, ph measurement, chromatographic measurement, filling and transportation, salt solution venom test environment: contaminated groundwater, flow injection analysis, sewage/sludge analysis, wastewater sampling, rainwater salt analyzer pharmaceutical industry: cosmetics preparation, prepared with extinction liquid, decomposition experimental device, fermentation control, harvesting cell culture medium, nutritional supply of culture bacteria. Printing industry: lithographic ink dosing, ink dosing wastewater treatment: lime dosing, polymer dosing, water treatment: chlorine analyzer, sewage ph control, silicone resin water cleaning, and so on.

What does a peristaltic pump do?

Chonry peristaltic pump is a type of tubing pump used for pumping a variety of liquids, they are also commonly known as roller pumps /tubing pumps or liquid handling pump. It works with a flexible hose (pipe/tube). Put the standard tube inside the pump casing. Tighten the hose with the pressure block, and start the motor, the motor drives the roller to rotate, and the roller squeezes the hose to make the liquid flow. Thereby transporting liquid.

Can peristaltic pumps pump air?

Yes, the Chonry Peristaltic pump can pump air. Our peristaltic pump’s standard pressure is 1.4 bar (20.3 psi). The Max Vacuum pressure is about -1 bar, The work pressure should be in this range. And pumping air means the pump dry work. will cause the tube easy to wear out. So if you want to pump the air, pls change the tube regularly.

Are peristaltic pumps self-priming?

When the Chuangrui peristaltic pump is started, the pump itself can automatically remove the gas in the suction pipe and fill it with the liquid being sent, that is, the pump does not need to be filled before starting.

Peristaltic pumps do not require pumped fluid to be continually present pumps can run dry, without costly downtime or repairs. The recovery of the hose or tube creates a powerful self-priming action and allows the pumps to move liquids containing entrapped air or that can off gas.

How deep can a peristaltic pump work?

The use of a Chonry peristaltic pump for a water sampler always needs to consider the vertical suction distance. A peristaltic pump has a theoretical lift limit of about 10 meters. The reality of it is this: most peristaltic pumps lift water a maximum of anywhere between 5-8 meters depending on the pump.